30.04.2024

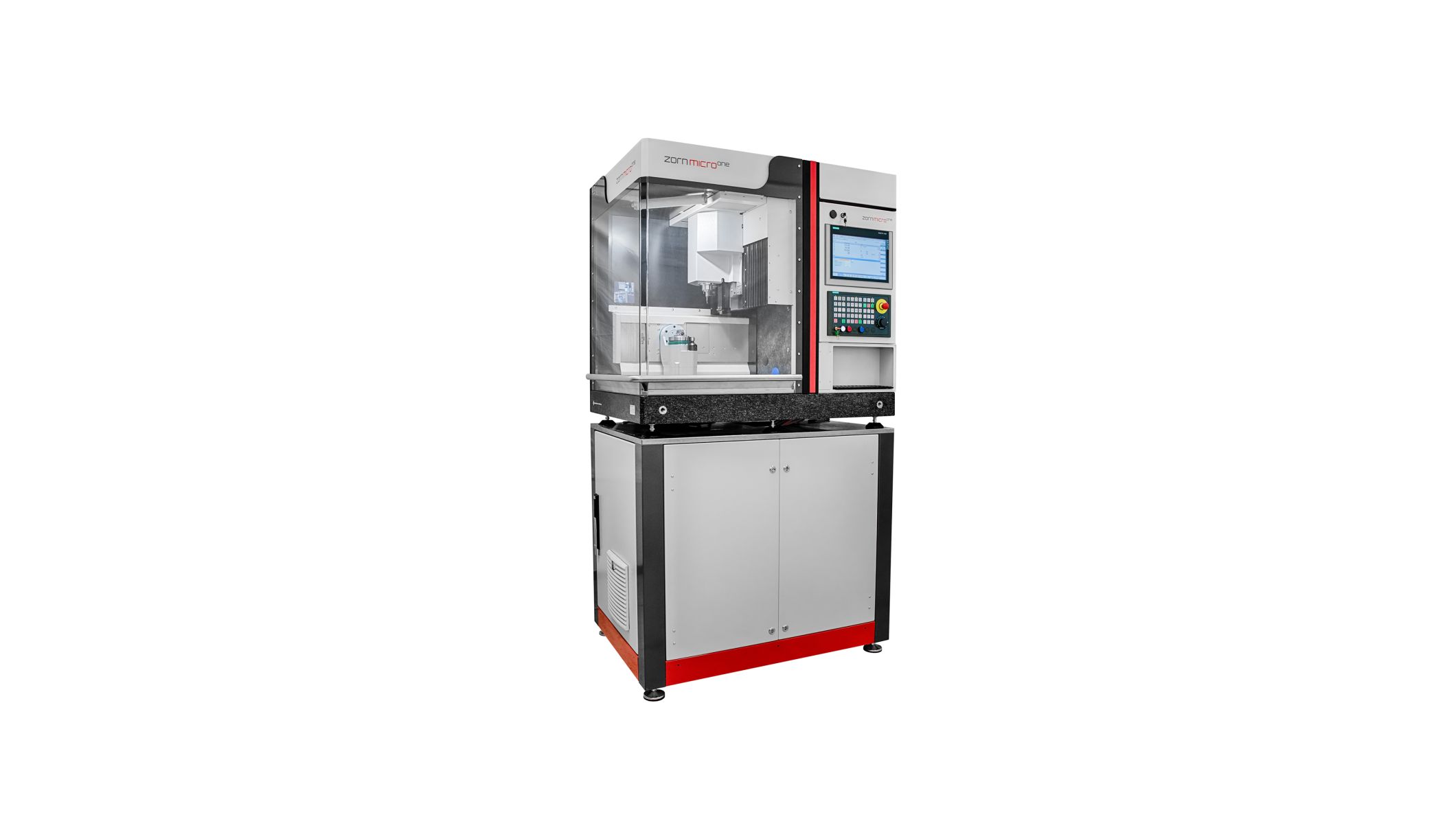

Discover the URMA portfolio for your high-precision application at the EPHJ! URMA will demonstrate live the production of a watch case using the ZORN microone and HAAS CM-1. The data transmission and production monitoring solutions are enabled by iCam.

With the EMCO MAXXTURN 25, URMA presents the machine concept for the efficient production of precision and turned-milled parts.